“I’ve used other 3D machines here and decided to use Solidscape because of the castability of the materials…and, a very important thing, the technical support part of it.”

Jules Barba, JB Diamonds & Fine Jewelry Owner

Full customization

JB Diamonds & Fine Jewelry is a family owned and operated business that specializes in custom jewelry and creating family heirlooms. The company has been serving Southern California since 1983 and has established a well-earned reputation.

“It’s known in the community: If you want to have something done, there’s only one place to go — JB Diamonds,” says owner and artist Jules Barba, who routinely renders the visions of his clients into reality. “If you can think of it, we can make it.”

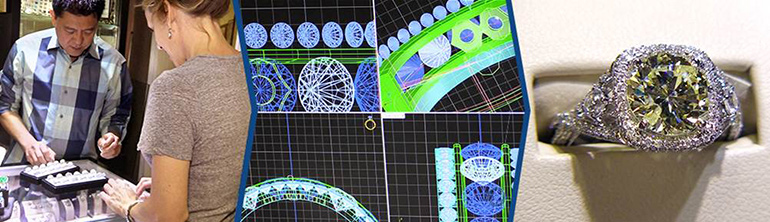

JB Diamonds uses 3D CAD and Solidscape 3D printers to produce perfect, custom designed family heirlooms

JB Diamonds artists sketch jewelry designs on paper and translate them into CAD via Matrix. The fine jewelry manufacturer then relies on its Solidscape® 3D printers to create high precision wax models, from which pieces are cast into precious metals.

Inspired details

JB Diamonds’ process requires intricate wax models. Carving them by hand, however, is a challenge for jewelers.

“If you’re right-handed, the right-hand side of the models will always be more perfect than the left-hand side,” explains Barba, adding that skilled but unavoidably imperfect handwork results in highly variable angles within each piece. “When you’re dealing with miniature products like jewelry, those little details make a big difference. Your eye picks up on it right away.”

Using 3D CAD software and Solidscape printers eliminates the inconsistencies. “When you say 45 degrees, it’s exactly 45 degrees,” Barba laughs. “That’s what makes the difference. You have the perfect symmetry and the perfect angles.”

Customer satisfaction

JB Diamonds works with customers to create truly unique fine jewelry — new family heirlooms to cherish. Using Solidscape printers, Barba can also produce them remarkably quickly. Once the design is finalized, he works with his expert staff to print a 3D wax model almost immediately. The casting only takes a few days more.

“I tell my client, ‘You don’t have to call, you just can come in anytime you want.’ [The piece will either be] in the 3D printing side or the metal manufacturing side. Between those two rooms, the next thing is it’s done,” says Barba. “The most exciting thing is going through the whole process of making, collaborating with the client. And when the product is actually finished, you can see the reaction of a very happy, satisfied client.”

Customer Profile - Creating Family Heirlooms

Wax master Precious metal final product| jbdiamonds.com |

| Industry Jewelry |

| Process Wax modeling followed by lost wax investment casting |

| Benefits Castability Technical support Perfect angles Fine detail Fast process Minimal downtime High finished quality |